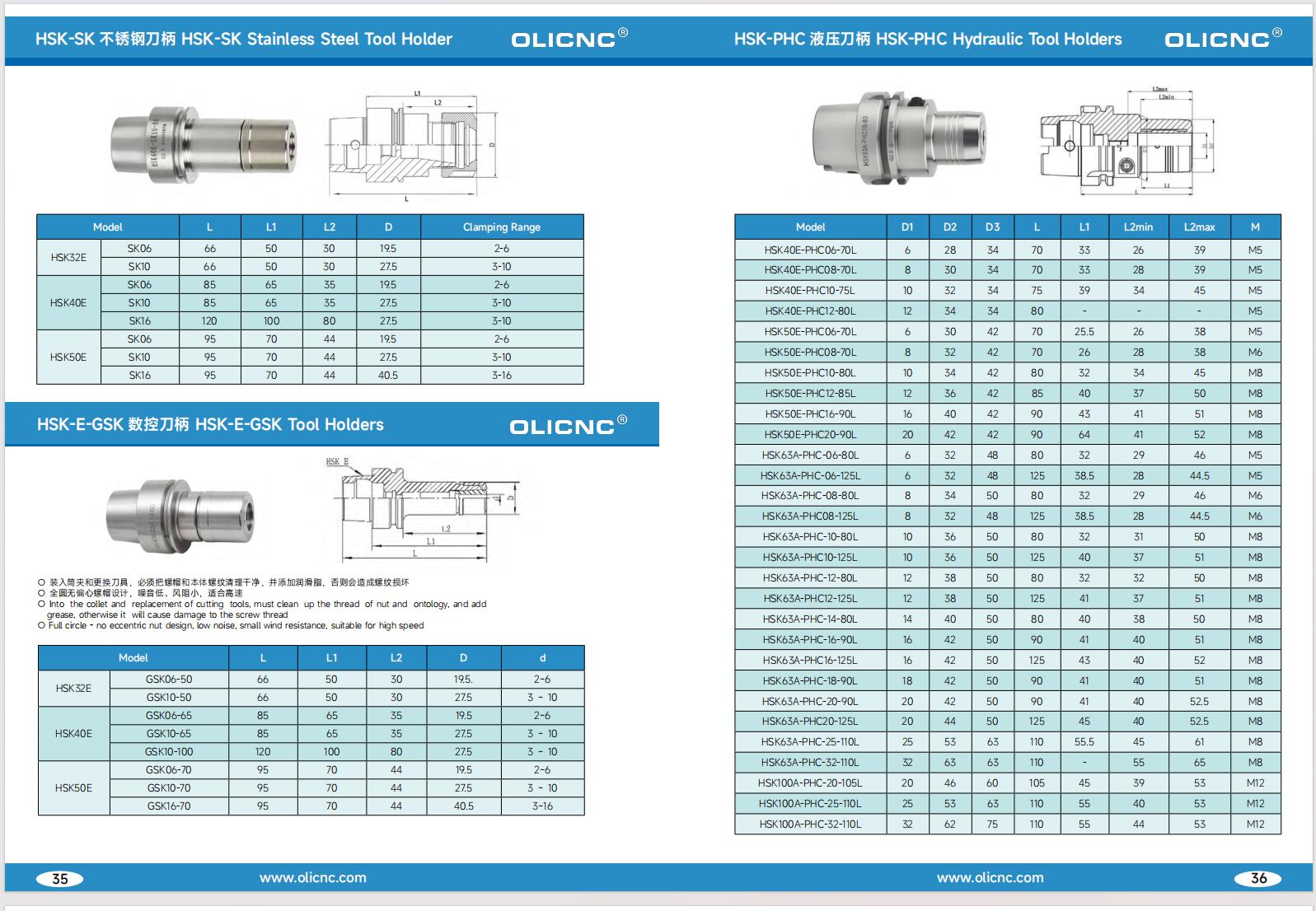

HSK63A Hydraulic Collet Chucks Holders for CNC

1. What factors affect the tightening force of the hydraulic tool holder?

The hydraulic tool holder is an important component that connects the tool holder and the machine tool spindle. The tightening force is directly related to the processing accuracy and safety. However, the tightening force of the hydraulic tool holder is not the greater the better, but should be within a certain range, otherwise it will affect the processing quality and life. So, what factors affect the tightening force of the hydraulic tool holder?

1. The thickness of the lubricating oil film : The good state of the lubricating oil film can reduce friction and achieve the effect of reducing the tightening force.

2. The quality of the coating : The quality of the coating affects the matching degree between the tool holder and the spindle taper, thereby affecting the tightening force.

3. Tool holder material and diameter

The material and diameter of the tool holder are important factors affecting the tightening force. Usually large diameter and high strength tool holders require greater tightening force.

4. The quality of the machine tool spindle taper

The quality of the machine tool spindle taper affects the contact between the tool holder and the spindle, thereby affecting the tightening force.

2. How much force should be used to tighten the hydraulic toolholder?

After the above analysis, we conclude that the tightening force of the hydraulic toolholder should be between 35-45 Newton meters.

How to tighten the hydraulic toolholder in a scientific way? Here are the specific steps:

1. First make sure that the spindle and the knife clamp are flush, and insert the toolholder into the knife clamp.

2. Tighten gently by hand to ensure that there is no debris caught between the toolholder and the knife clamp or there is any looseness.

3. With the help of a wrench, gradually increase the tightening force. When tightened to about 30-35 Newton meters, a special torquer can be used for fine adjustment until it meets the range of 35-45 Newton meters.

4. After the tightening force reaches the requirement, remember to turn the wrench slowly once to make the toolholder and the spindle move more smoothly.

In short, the tightening force of the hydraulic toolholder should meet the range requirements, and scientific methods are required when tightening to ensure its safety and stability.

For further relevant product images or details, please visit our company website

our company mainly manufacture series of Tool Holders :

- Portaherramientas: Pinzas ER, Collets Chucks, Portabrocas,Boring Head ,etc;

- Accesorios le máquina: Machine Vices, Dividing Head, Rotary Tables,etc;

- Wood-working metals: Live Center, Steel Clamping kits, Lathe Chucks;

- Tool Bits: CNC Turning Holder , U Drill , Insert , End Mill

Olicnc,Pinzas ER, Portaherramientas, Accesorios le máquina

Olicnc,Pinzas ER, Portaherramientas, Accesorios le máquina